Case

Studies, Use of the GreenSeeker Sensing and OSU Nitrogen

Management Strategy, Also, Central City, Nebraska (CV correction)

Case

Studies, Use of the GreenSeeker Sensing and OSU Nitrogen

Management Strategy, Also, Central City, Nebraska (CV correction)GreenSeeker Nitrogen Fertilizer Applicator near Minden, NE, with Andy Holzwarth and Kevin Raun, July 2008

You Can Contact Any Holzwarth who sells the GreenSeeker Systems at 316 650 2672

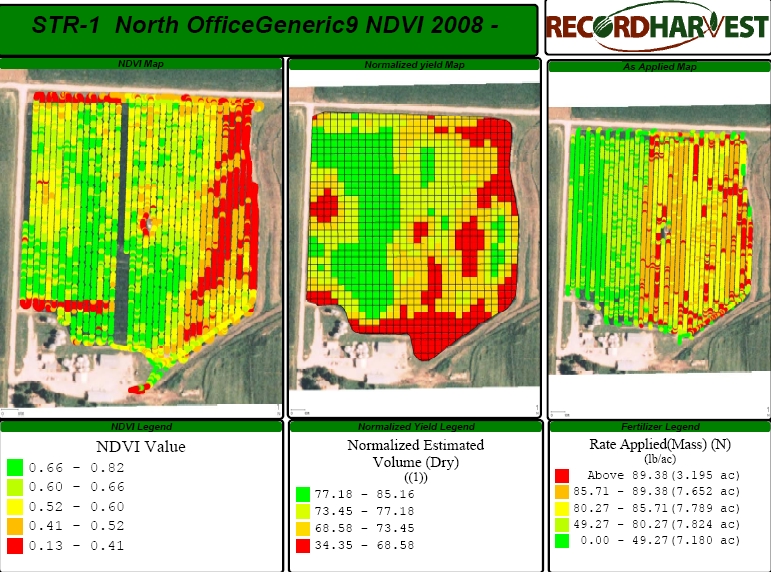

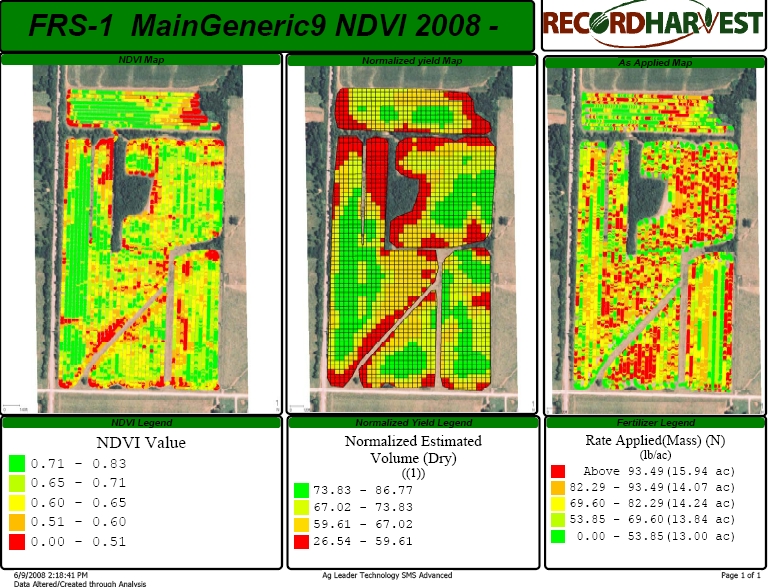

Justin Ogle with Record Harvest Enterprises near Nevada, MO illustrates the AA applicator tied into a GreenSeeker Variable N Rate system. Below are a few of his NDVI maps, and VRT application of N using the OSU V1.3 corn algorithm.

Bob Woods

Bob Woods

Area Extension Agronomy Specialist

230 W. Okmulgee, Suite C

Muskogee, OK 74401

918-686-7800

Regional Extension

presentation on the use of the GreenSeeker Sensor System

Roger Gribble

OCES NW Area Agronomist

Enid, OK

BRENT A. RENDEL

Ag Production: wheat; milo; corn; soybeans Activities: First Presbyterian Church; Green Country Co-op Assn.; U.S. Navy; OK Soybean Assn./ASA; FFA;

John,

Just wanted to let you know that I was able to download all the files and all worked fine. Stan was off in Colorado on Monday, but I got the files onto his Ipaq and got several fields sensed Monday.

I like the program pretty well. A few constructive comments from my initial use on 6 fields:

1. I like seeing 2 ramps & average side-by-side, but would love it if I could go to 3 or 4. 4 would allow me to sense 2 different ramps down and back.

2. If I analyze a file that only has 1 trip after analyzing a 2-trip file, the 2nd trip data remains on the display. The average data is correct (matches the 1st trip data), but it took me a little while to figure out that I just needed to ignore the 2nd trip info when I was processing a single-pass file. By backing out of the analyzer and then re-entering, it starts with everything all zeroed out and does not cause a problem, but I typically analyze all my ramp sensed files after I've gathered many fields of data and its sometimes hard to remember what ramp had 1 pass and what one had 2.

3. The NDVI(0) numbers coming out of the analysis are not repeatable for the #1 ramp. The second ramp NDVI(0) in the data set always calculated the same. The change was minor and rarely affected the final N recommendation more than a pound or 2. It seemed to happen with both high and low RI's. Not a big issue.

More later after my next use. Thanks.

Brent Rendel

Randy,

That sounds good. It now looks like I will still be in town next Monday, so I will probably wait until then to check the ramps. It will still be too early, but I think there may be some value in gathering the data anyway. I only have 6 fields to check, so it will only take 1-2 hours to grab them all.

I originally had a throttle valve at the outlet of the solenoid valve for the 8x boom to allow for tweeking the flow down on those tips, but it turns out that the 1/2" hose leading to the boom provided all the throttle necessary at that high flow rate. In fact, I had to remove the throttle valve from the outlet because even fully open, it was too much restriction.

Before wheat, I am going to reconfigure the 8x boom to 3/4" out of solenoid valve and then tee it off to feed the boom in 2 separate locations. I'm getting way too much pressure drop along the line before reaching the outer-most tips. I had to blank off the end tips of my rig (dropped to 5 x 20" vice 7 x 20") to get the corn ramps down. I think splitting out the input will solve this and give me a full 10' wide ramp.

For this go-around, just configure the ramp program for the numbers I sent. Since I am still not electronically calibrated on speed, that will provide the 90% solution. I hope to add at least a GPS speed reading for the next go-around so that I can address that error source. I figure it is my biggest source right now.

Thanks for the help.

Brent